The difference between the principle of heavy hammer crusher and impact crusher

The difference between the principle of heavy hammer crusher and impact crusher

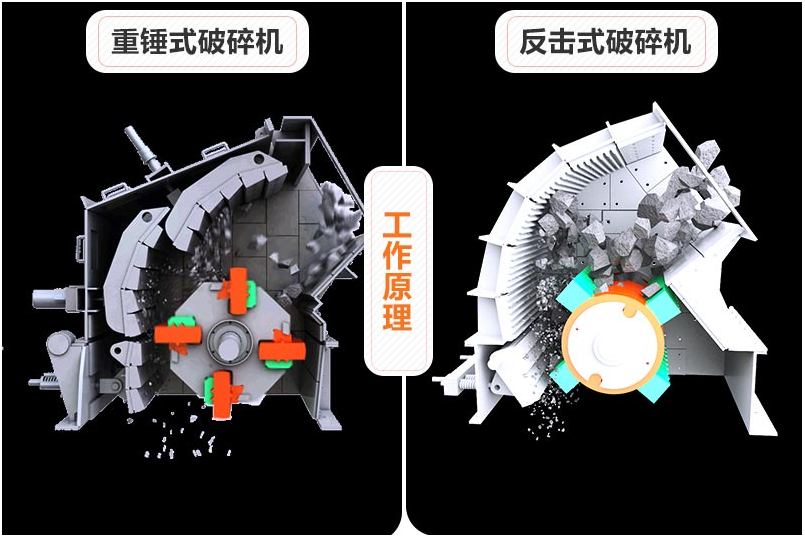

Hammer crusher: It is crushed under the action of the high-speed rotating hammer head, then rebounds, and is further crushed by hitting the impact plate at high speed. During the whole process, the ore is crushed many times.

Impact crusher: The material first hits the rotating hammer head and is hit on the impact plate at high speed, so that the crushed material is thrown to the impact plate at the other end of the crushing chamber at high speed along the tangent direction, and is crushed again. A piece of stone is crushed many times.

Comparison of the principles of heavy hammer crusher and impact crusher

III. Difference in the scope of application of materials

Hammer crusher: can directly crush materials with a large particle size of 600-1800 mm to 25 or less.

Impact crusher: suitable for processing brittle materials with a side length not exceeding 500 mm and a compressive strength not exceeding 350 MPa.

IV. Analysis of the advantages of hammer crusher and impact crusher

Advantages of hammer crusher:

(1) Large crushing ratio, can be crushed and shaped in one time, the product particle shape is good, and there is less over-powdering phenomenon;

(2) Hammer crusher integrates coarse crushing and shaping functions, has no screen plate, and reduces blockage;

(3) The output of a single machine can reach 3,000 tons per hour, which is very useful in large sand plants.

Advantages of impact crusher:

(1) Strong adaptability, can crush hard, soft, brittle and tough materials with high water content, and the finished products are mostly cubic with uniform particle size.

(2) The crushing ratio is large, generally 20-50, and the largest is above 150. It can complete medium and fine crushing operations at one time, greatly simplifying the production process.

(Live chat)

(Live chat)