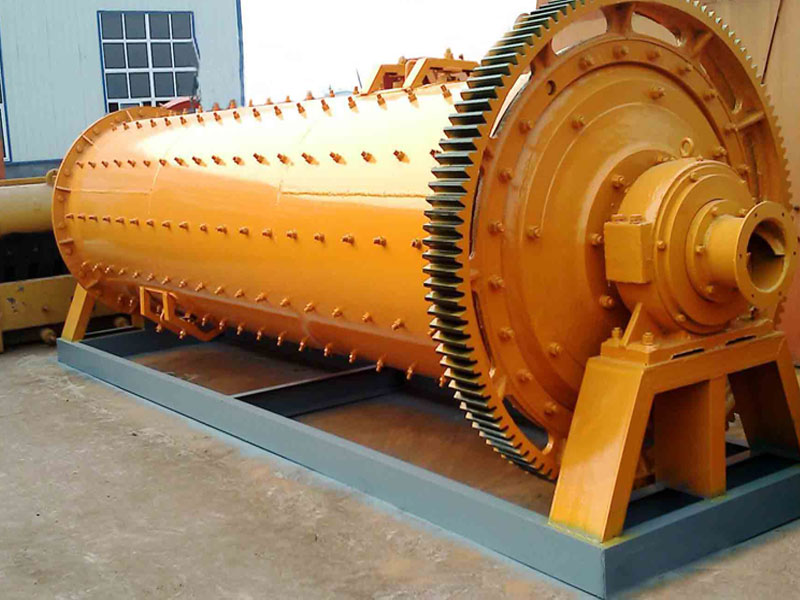

Introduction of Raw Mill:

The raw material ball mill is key equipment for the grinding process of the raw material after the crushing process of it. It is widely used in the cement silicate product industry, new type construction material industry, refractory matter industry and glass ceramic industry for grinding various minerals and materials. After long term experience of design and manufacture, our company now has series of raw material ball mill with various specifications to meet with different requirement from our customers especially for grinding slag and cement. We can also offer customized design according to different material and different technical requirements.

Features of Raw Mill:

Our company adopts suitable transmission methods according to different specifications. We have brim drive and center drive as transmission form. The cylinder adopts new type step lining to increase the grinding area. And it is easily repairable and changeable. The new designed separate-chambered structure adopts flexible lifting blade and fixed lifting blade and it is easily fixed and repaired.

Working Principle of Raw Mill:

The cylinder will rotate by the transmission device. Due to the inertial centrifugal force, the steel balls will stick on the liner plate and rotate with the cylinder together. When the steel balls come to a certain height, it will fall down by gravity and impact the raw material. And the repeated going-up, falling down, slide and roll of the steel balls can grind the raw material together with the liner plates.

Technical Parameters of Raw Mill

|

Specification (m) |

Ball Mill Type |

Transmission Type |

Reducer |

Motor Power (kw) |

Capacity (t/h) |

Weight (t) |

|

|

Model |

Ratio |

||||||

|

φ1.5×5.7 |

Open flow |

Brim |

ZD40 |

3.55 |

130 |

4.5-6 |

25.8 |

|

φ1.83×6.4 |

Open flow |

Brim |

ZD60 |

4.5 |

210 |

7.5-15 |

43 |

|

φ2.2×6.5 |

Circle flow |

Brim |

ZD70 |

5 |

380 |

14-26 |

60 |

|

φ2.4×7 |

Circle flow |

Brim |

ZD70 |

5 |

475 |

24-28 |

81 |

|

φ2.4×10 |

Circle flow |

Brim |

ZD80-4-Ⅱ |

6.435 |

570 |

32-36 |

118 |

|

φ2.6×10 |

Circle flow |

Brim |

JDX710 |

6.3 |

800 |

45-50 |

130 |

|

φ3×9 |

Open flow |

Brim |

JDX800 |

6.3 |

1000 |

55-60 |

158 |

|

φ3.2×9 |

Circle flow |

Brim |

MBY900 |

7.1 |

1250 |

62-65 |

195 |

|

φ3.5×10 |

Open flow |

Brim |

JDX900 |

5.84 |

1250 |

70-75 |

200 |

|

φ3.8×7.5 |

Circle flow |

Brim |

JDX900 |

5.6 |

1600 |

80 |

233 |

|

φ4.6×10+3.5 |

Circle flow |

Central shaft |

JQS3550 |

15.1 |

3550 |

190 |

415 |

|

φ4.6×10.5+3.5 |

Circle flow |

Central shaft |

JQS3550 |

15.1 |

3550 |

210 |

476 |

(Live chat)

(Live chat)